Quality Management

To provide reliable products, we perform strict quality control and active pre-quality securement to maximize the realization of customer satisfaction. Also, Kyungrim Tech is a leader in the wire harness manufacturing industry through achieving zero-defect quality of products and expansion of sales in the global market.

Research and Development (R&D)

R&D performance through partnership with J.A.M. (Japan Automatic Machine Co., LTD.)

-

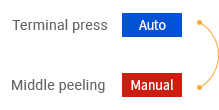

Before improvement

Terminal pressing & the middle peeling through the Stage 2 process

First process

2nd process

-

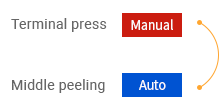

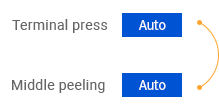

After improvement

Defect rate is reduced and productivity is increased through the full automatic process in Stage 1

Process after improvement

R&D performance through partnership with J.A.M. (Japan Automatic Machine Co., LTD.)

On performing the process within the cutter & press, additional facility of vision camera is applied and improved automatic process is added to enable real-time process inspection, reducing the process defect rate up to 90% compared to the existing process, and to increase the productivity up to 15%

- Before improvement

- After improvement

90% Decrease

in defective proportion

- Before improvement

- After improvement

15% Increase

in productivity

R&D performance of improving the circuit tester through partnership with CIS&S

-

Before improvement

Previous testing machine

- Composition

- Tester, Inspection board, Watertight tester, Monitor, Keyboard, mouse

- Performance

- Circuit test, Watertight test, Storage of test records

- Attributes

- Requires wide space, difficulty in arranging the wires, Complex initial setting, Button operation

-

After improvement

Improved testing machine

- Composition

- Tester, Inspection board

- Performance

- Circuit test, Watertight test, Storage of test records

- Attributes

- Does not require much space, easy arrangement of wires, Simple initial setting, Touch operation

R&D performance of improving the circuit tester through partnership with CIS&S

Increase 15% in production efficiency and save 40% cost per year by developing a circuit checker in configuration with an automatic and touch devices (Simple setting and touch operation compared to existing ones)

- Before improvement

- After improvement

40% Decrease

in costs

- Before improvement

- After improvement

15% increase

in productivity

Certifications

-

- SQ Certifications

- Establishment of objectivity and transparency in supplier selection

- Securing reliability through the certification system and efficiency in management

- Elitism through specialization and standardization

-

- Enterprise Institute

- Enterprise Institute certification

-

- ISO 14001

- International environmental management system certification

-

- IATF 16949

- International quality management system certification

-

- Korea Industrial Technology Association Membership

-

- Confirmation of a Corporation specializing in materials and parts equipment

-

- Membership card of Gyeongsangbuk-do Exporter Corporation Association

-

- Certificate of Designation Small Giant Company of Korea

-

- Certificate for KOSHA-MS(Occupation Safety and Health Management System)

-

- CIRCUIT AND SEALING INSPECTION SYSTEM FOR WIRE HARNESS FOR AUTOMOBILE LAMP WITH

-

- Artificial Intelligence Appearance Inspection System for Wiring Harness

-

- Test device wire harness circuit and ceiling for the car lamps

-

- Selection of Regional Innovation Leading Companies in Gyeongsangbuk-do

-

- Global Small and Medium Business 1,000+ Company Designation Letter

Inquiry

Please submit any inquiries to Kyungrim Tech. Kyungrim Tech’s professional will assist you.

Inquiry