Development Process

Industry leading products are developed through continuous efforts and enterprise-wide quality innovation.

-

Step 01

Customer development request/Discussion

Materials and circuits discussion (Structural review), Process setting

-

Step 02

Manufacturing drawings design

2D & 3D Designs, Circuit verification per function, Optimization of materials composition and path setting

-

Step 03

Sample production/Review

Sample manufacturing, Design review, Sample review

-

Step 04

Process management check

AP(Advanced Production),

QP(Quality Planning)

Manufacturing Process

Kyungrim Tech aims for zero-defect qualified production through systematic manufacturing process and 5-stage inspections.

-

Step 01

Primary inspection (1st)

Raw materials management, Primary inspection

-

Step 02

Automatic cutting & Automatic pressing

Automatic cutting & Automatic pressing

-

Step 03

Automatic sheath peeling

Automatic Middle/Sheath peeling

-

Step 04

Procedural press test (2nd)

Automatic press, Joint press, Procedural press tests

-

Step 05

Automatic assembly

Thermal contraction on joints, SUB, Assembly

-

Step 06

Circuit test (3rd)

Manual press, Joint press, Procedural press tests

-

Step 07

Final visual inspection (4th)

-

Step 08

Consignment inspection (5th)

-

Step 09

Delivery

Efficient inventory management

Reliability Test

The Reliability tests are conducted for selection and improvement on reliability of products for respective stages. Also, the tests are focused to verify the reliability of products throughout from the product planning stage to the actual use after delivery for securing the stable quality within the intended period.

-

Tensile force resistance test

The test is conducted to see whether the connection state of the solderless terminal maintains the standard measurement level.

-

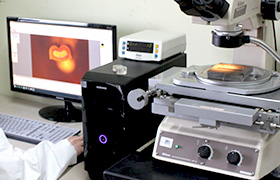

Compressed section test

The test is conducted to verify that all strands are covered on wire pressing, and check on strand breakaway on the press section, partial strand disconnection, breakage and shear.

-

Compressibility test

The test verifies whether the standard level of (Area of inner terminal wall after pressing / Cross-sectional sum of conductor strands before pressing) * 100 is maintained.

-

Standard voltage test

Equal voltage currents within the parts are checked.

-

Underwater voltage test

The test is conducted to check on the short circuits of the insulator from humidity.

-

Thermal shock test

The thermal shock test is conducted to evaluate the resistance of the parts on sudden temperature change. Starting from room temperature, the product is exposed to very low temperature (or very high temperature) for specific number of times and the process of exposure to very high temperature (or very low temperature) within a short period of time.

-

Isothermal-humidity test

Various parts and modules are applied with electrical shock in high/low temperature and high/low humidity environments to test the durability and reliability.

-

Complex vibration test

The product’s quality is tested by applying the vibration, temperature and humidity changes of the part.

Main Equipment

The production facility features wire cut, waterproof and terminal compression funtions.

- Manufacturing equipment

- Reliability equipment

-

- Automatic cutter & press KODERA CASTING C555

- The equipment is in charge of the total process of automatic cutting, peeling in the middle, pressing and assembly on the wire in accordance to the set standard. Especially, to solve the problem of deviation in press location / length occurred in low-price equipment, Kyungrim Tech introduced sub-motor in all top-quality equipment to purse high quality and performance

-

- Automatic cutter & press KODERA CASTING C515

- The equipment is in charge of the total process of automatic cutting, peeling in the middle, pressing and assembly on the wire in accordance to the set standard. Especially, to solve the problem of deviation in press location / length occurred in low-price equipment, Kyungrim Tech introduced sub-motor in all top-quality equipment to purse high quality and performance

-

- Automatic cutter & press J.A.M. JN-03WP

- The equipment is in charge of the total process of automatic cutting, peeling in the middle, pressing and assembly on the wire in accordance to the set standard. Especially, to solve the problem of deviation in press location / length occurred in low-price equipment, Kyungrim Tech introduced sub-motor in all top-quality equipment to purse high quality and performance

-

- Automatic cutter & press J.A.M. JA03SDA

- The equipment is in charge of the total process of automatic cutting, peeling in the middle, pressing and assembly on the wire in accordance to the set standard. Especially, to solve the problem of deviation in press location / length occurred in low-price equipment, Kyungrim Tech introduced sub-motor in all top-quality equipment to purse high quality and performance

-

- Applicator (Side type) J.A.M. 780 759

- As a key part in the automatic cutter & press, an applicator is a product that connects the shear and the terminal, and the metal is embodied on combination to enable the assembly

-

- Applicator (Side type) J.A.M. 730759-3S

- As a key part in the automatic cutter & press, an applicator is a product that connects the shear and the terminal, and the metal is embodied on combination to enable the assembly

-

- Applicator (End type) J.A.M. 760145

- As a key part in the automatic cutter & press, an applicator is a product that connects the shear and the terminal, and the metal is embodied on combination to enable the assembly

-

- Applicator (End type) J.A.M. 730220

- As a key part in the automatic cutter & press, an applicator is a product that connects the shear and the terminal, and the metal is embodied on combination to enable the assembly

-

- Seal oil remover DOOSUNG SONA

- The oil on the surface of the wire connector is removed automatically

-

- Ultrasonic cleaner Uil UltrasonicUIL-1H600W

- Foreign substances on the applicator inside the automatic cutter & press are removed

-

- Wire heater BUKWANG

- The temperature of the wire is maintained constantly

-

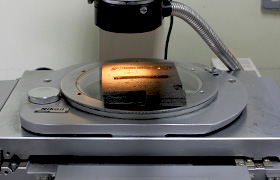

- Projector MITUTOYO PJ300

- The inspecting object is magnified and projected optically in exact magnification to measure the shape, size and angle on the screen

-

- Toolmaker’s microscope NICON MM-40 / 200 times

- Size, angle and contour of an object are measured

-

- Voltage Drop Tester STR KL-5530

- Standard voltage is measured

-

- Grinder kYUNGDO 600RPM

- Standard voltage is measured

-

- Micrometer monos 63127167

- The height of the pressed terminal is measured

-

- Underwater voltage tester TESKO TOS5301

- Short circuit of the insulator due to humidity is checked

-

- Digital calipers MITUTOYO CD-20CPX

- The width of the pressed terminal is measured

-

- Resistance meter HIOKI 3540

- The battery inside the multi-meter is used to apply the voltage to the resistance connected to the external probe for measuring the current

-

- Tension and compression tester DAE SUNG TECH D5K1044

- The standard of maintaining the connection state on the pressed terminal is measured

-

- Complex vibration tester RCTCOMBINED TEMP & HUMID CHAMBER

- Changes in vibration, temperature and humidity are applied on the product to test the quality

-

- Thermal shock tester OSUNG ST CO.OST-TST06-D01

- Heat is applied on the material or part that is to be tested from very high temperature (or very low temperature) to very low temperature (or very high temperature) to find existing defects or to verify the heat resistance characteristic

-

- Temperature-Humidity tester OSUNG ST CO.OST-THB04-C10

- Various parts and modules are applied with electrical shock in high & low temperature and high & low humidity environments to test the durability and reliability

Inquiry

Please submit any inquiries to Kyungrim Tech. Kyungrim Tech’s professional will assist you.

Inquiry